POWERTRAIN SYSTEM 2022

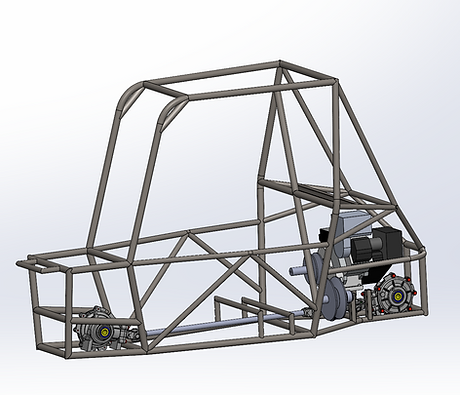

PACKAGING AND LAYOUT

Packing the engine, gearbox, CVT, differentials, and other drivetrain components into a small single seater off-roading vehicle is not an easy task. I am focused heavily on powertrain packaging in this year's powertrain system design. I lowered the center of gravity of the vehicle by lowering the engine and powertrain components, and reduced the wheel-base by improving gearbox and differential coupling. The lowered center of gravity and reduced wheelbase will significantly improve handling characteristics of the vehicle.

GEARBOX FATIGUE AND STRESS COMPUTATIONS

I started the process by determining the final drive ratio of the power train system. I wanted to improve low-end torque and acceleration so I choose a final drive ratio slightly lower than last years design. Working from the desired final drive ratio and the differential gear ratio I determined a gearbox ratio of approximately 2.10. I computed the allowable and working loads for the gears, shafts, and bearings by hand to optimize the design for weight.

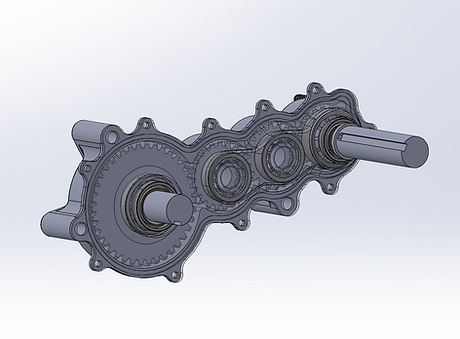

GEARBOX DESIGN & CAD

Using the results from the fatigue and stress computations I chose gears and bearings that met the required working loads. I designed the shafts to fit the gears, bearings, and seals. Using SolidWorks I modeled and imported the internal components and designed a housing to contain them.

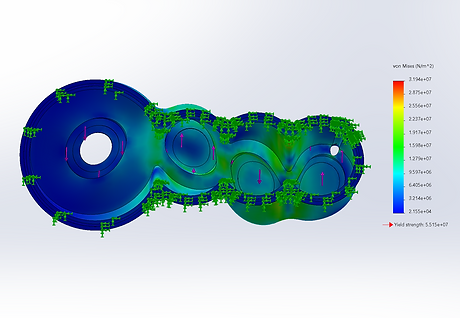

GEARBOX FEA

To validate my gearbox housing design I setup and ran an FEA simulation. I fixed the outer flange of the housing and applying the reaction force at each of the bearings. The FEA computed Von Mises stress is under the yield stress of 6061 aluminum alloy, demonstrating that housing will not under go plastic deformation under maximum load.

HOUSING MANUFACTURING

The housing is CNC milled from billet 6061 aluminum. I wrote the CNC milling operations using NX CAM. The housing is divided into two halves, the body and the cover. Each half requires two setups: internals and externals. The manufacturing process utilizes many different milling operations, from planar and cavity milling to drilling and tapping.

ASSEMBLY AND TESTING

After all components were manufactured I assembled the gearbox and integrated the powertrain system onto the vehicle. During extensive testing the powertrain system experienced zero failures.